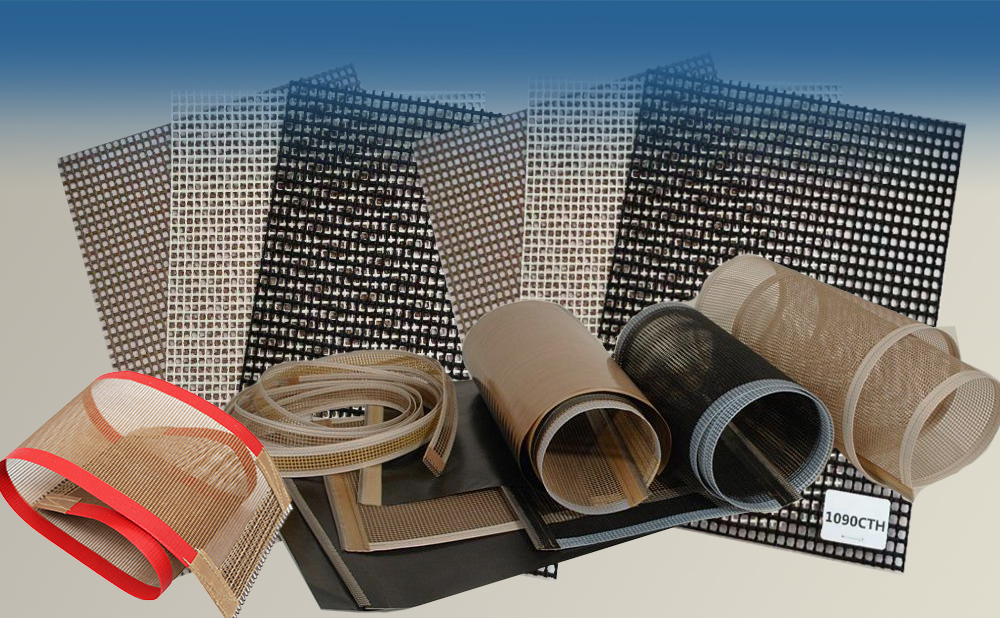

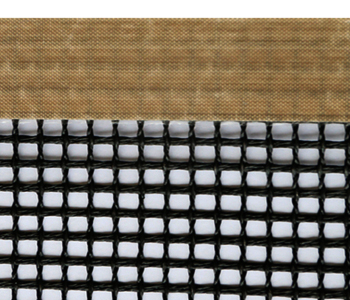

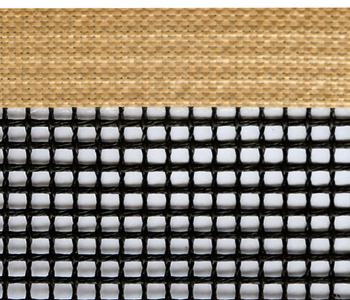

PTFE coated fiberglass dryer belts from the highest quality woven fiberglass substrates available. Our uniform PTFE coating impregnates and coats the fiberglass yarns resulting in excellent abrasion resistance and a low coefficient of friction, enhancing release of various coatings and materials. Designed to operate in extremes of both temperature and chemical exposure, the belts are suitable for gas, electric, infrared (IR), radio frequency (RF), microwave and ultraviolet (UV) conveyorized drying operations. This incredible substrate is then cut, sewn, sealed and laced to make drying / processing belts for a wide variety of industries.

We use many of our in-house coated fabrics and fabrication capabilities to manufacture high temperature, non-stick conveyor belts for use in a wide variety of industries. Sewing, thermal welding and lacing are just a few of our operations.In addition to coating fiberglass & Kevlar fabrics, we fabricate specialized high temperature belting for a variety of industries: Food Processing/Quick Serve Restaurant,Packaging,Screen Printing,Process Drying,moulded pulp egg packaging drying.

1, for low temperature -70 ℃, high temperature between 260 ℃, with a weather resistant, anti-aging. The practical applications, such as high temperature at 250 ℃ for 200 days, not only the intensity will not decrease, and the weight is not reduced;

2, non-adhesive: easy to adhere to any substance. Easy to clean the surface of a variety of attachment grease, stains or other attachments; paste, resins, paints, etc. Almost all sticky substance can be easily removed;

3, chemical resistant, resistant to acids, alkalis, corrosive aqua regia and various organic solvents.

4, good dimensional stability (extension coefficient of less than 5 ‰), high strength. Have good mechanical properties.

5,Teflon mesh belt resistance to bending fatigue can be used for smaller wheel diameter.

6, chemical resistance, non-toxic. Resistant to almost all pharmaceutical items.

7, fire retardant.

8, the belt --- permeability permeability, reduced heat consumption, improved drying efficiency.

| Fiberglass Belts Technical Data | |||||||

| No. | Mesh Size | Material | Thinkess | Weight | Temp Resistance | Max width | Tensile Strength |

| 6001 | 1X1mm | Conveyor | 0.5mm | 440g/m2 | -70-260℃ | 4m | 1800/1650N/5cm |

| 6001B | 1X1mm | Conveyor | 0.5mm | 440g/m2 | -70-260℃ | 4m | 2400/1600N/5cm |

| 6002 | 2X2mm | Conveyor | 0.7mm | 450g/m2 | -70-260℃ | 4m | 2200/1500N/5cm |

| 6003 | 4X4mm | Conveyor | 1.0mm | 545g/m2 | -70-260℃ | 4m | 1350/1700N/5cm |

| 6004 | 4X4mm | Conveyor | 1.0mm | 545g/m2 | -70-260℃ | 4m | 1350/1700N/5cm |

| 6007 | 4X4mm | Conveyor+Kevlar | 1.2mm | 570g/m2 | -70-260℃ | 4m | 3300/2300N/5cm |

| 6008 | 4X4mm | Conveyorl | 1.0mm | 570g/m2 | -70-260℃ | 4m | 2800/3000N/5cm |

| 6012 | 4X4mm | Conveyorl | 1.0mm | 630g/m2 | -70-260℃ | 4m | 1800/3000N/5cm |

| 6010 | 4X4mm | Kevlar | 1.0mm | 460g/m2 | -70-260℃ | 4m | 3300/2050N/5cm |

| 6013 | 10X10mm | Conveyor | 1.0mm | 460g/m2 | -70-260℃ | 4m | 1400/1000N/5cm |

| 6014 | 0.5X1mm | Conveyor | 0.5mm | 440g/m2 | -70-260℃ | 4m | 2200/1500N/5cm |

| 6015 | 2X2.5mm | Conveyor | 0.9mm | 520g/m2 | -70-260℃ | 4m | 2200/1500N/5cm |

| 6016 | 2X2.5mm | Conveyor | 0.9mm | 615g/m2 | -70-260℃ | 4m | 3000/2000N/5cm |

| 6018 | 4X4mm | Conveyor | 0.9mm | 735g/m2 | -70-260℃ | 4m | 2000/4000N/5cm |

| 6019 | 4X4mm | Conveyor | 0.9mm | 890g/m2 | -70-260℃ | 4m | 2300/4000N/5cm |

| 6032 | 4X4mm | Conveyor | 0.9mm | 710g/m2 | -70-260℃ | 4m | 2500/3000N/5cm |

| 6033 | 4X4mm | Conveyor | 0.9mm | 830g/m2 | -70-260℃ | 4m | 3500/3500N/5cm |

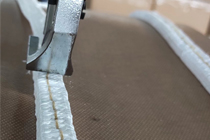

Belts PTFE Film Edge Reinforcement: PTFE fabric reinforcement is made of 0.13mm or 0.18mm thick PTFE high temperature cloth for edge strength, durable and anti-pressure.

It extends the using life of PTFE mesh belt and PTFE high temperature cloth conveyor belt as reinforcement materials.

Belts PTFE Film Edge Reinforcement: PTFE fabric reinforcement is made of 0.13mm or 0.18mm thick PTFE high temperature cloth for edge strength, durable and anti-pressure.

It extends the using life of PTFE mesh belt and PTFE high temperature cloth conveyor belt as reinforcement materials.

PTFE Edge Reinforcement: PTFE Film,PTFE red film, black ptfe film, red ptfe film, blue ptfe film.

PTFE Edge Reinforcement: PTFE Film,PTFE red film, black ptfe film, red ptfe film, blue ptfe film.

Clients mostly choose is red and black ptfe film because teflon mesh belt common color is brown and black.

Teflon mesh belt and teflon fabric conveyor belt are reinforced by ptfe film by welding machine in high tmeperature environment.

Reinforcement width: 4cm / 5cm

BeltsKevlar Reinforcement: Kevlar reinforcement cloth is also called PTFE coated kevlar cloth.

It is a new composite materials and coated by PTFE emulsion.

BeltsKevlar Reinforcement: Kevlar reinforcement cloth is also called PTFE coated kevlar cloth.

It is a new composite materials and coated by PTFE emulsion.

It is used as teflon mesh belt and teflon fabric conveyor belt reinforcement.

Because of composite features, it has good tensile strength, anti-cut performance, durable, anti-pressurization, non-stick performance.

It has long-time using features.

textile, printing: printing drying, dyeing cloth drying, shrinking and drying fabrics, non-woven bake drying, drying room conveyor belt.

Screen printing: pine dryer, offset printing, UV curing machine, paper, oil drying, UV drying, plastic silk screen drying bake, drying room conveyor belt.

Other items: high-frequency drying, microwave drying, freezing and thawing of various types of food, baking, heat shrink packaging materials, general moisture dry goods, flux type fast drying ink drying room conduction band.

Where the required heat transfer romantic occasions and thermal processing conditions, are suitable for use Teflon mesh belt.