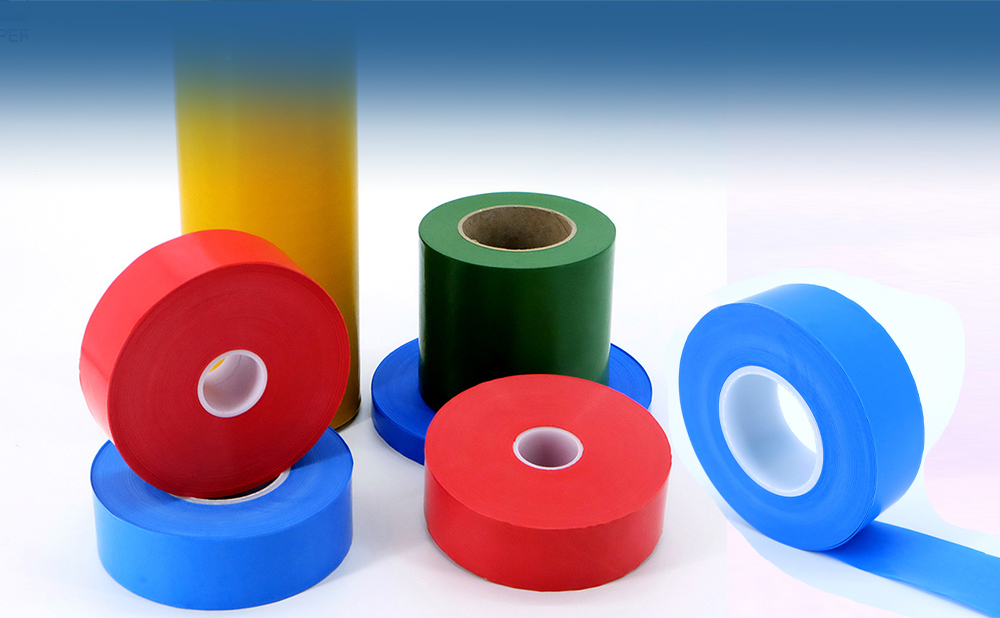

PTFE color film is a type of PTFE directional or non directional color film made by adding a certain amount of colorant to suspended PTFE resin, molding, sintering, turning, and rolling to thirteen colors, including red, green, blue, yellow, purple, brown, black, orange, and white. PTFE color film can be added with a certain amount of colorant, which has good electrical insulation,Good resistance to rodent bites and wear, preventing internal cables from being worn out. It's suitable for insulation and classification recognition of wires, cables, and electrical components.

The PTFE activation film is a thin film formed by surface activation treatment of PTFE film, filled film, and colored film. The addition of pigments, glass fibers, carbon fibers, graphite, bronze powder and other fillers to the product further improves its performance after activation treatment. It can be compounded with rubber, metal, and other materials, and can also be used to make special tape, meeting the design requirements. Widely used in light industry, military industry, aerospace, oil fields, and other fields.

After high-temperature hot pressing, the thickness of the turning film becomes more accurate. This treatment method is the process of orientation. Omnidirectional film refers to a film with a thickness of 0.10mm or less. For example, a 0.05mm film is formed by hot pressing and stretching a 0.10mm thick turning film, and the thickness is reduced by half. For thicknesses exceeding 0.10mm, the film after directional treatment is a semi directional film. The molecules on the surface of PTFE are extremely lazy and do not like to combine with other molecules, so it has non stickiness.

After soaking in chemical solution, the turning film breaks and damages the surface molecular structure of the film, and the color also changes. This turning film is called a nanoparticle film, and the back of this film can be stamped with double-sided adhesive to form some adhesive pads.

1. Has good drug resistance and is almost non corrosive to acids such as nitric acid, sulfuric acid, hydrochloric acid, phosphoric acid, and alkaline substances such as caustic soda.

2. It has good electrical characteristics such as low dielectric loss, high insulation resistance, and breakdown voltage. Due to the extremely low dielectric constant and dielectric attenuation factor, as well as the high volume resistance coefficient, and being very stable over a wide range of temperature and frequency conditions, it can be used as a high-frequency insulation material.

3. It can be used within the temperature range of -100 ℃ to 260 ℃, with good mechanical toughness, good elongation even when the temperature drops below zero degrees, and good fire resistance.

4. Oily bearings with low surface tension in solid materials, low friction coefficient, strong lubricity, and good self-lubrication can be used in combination with various fillers to obtain good wear resistance, friction resistance, and cold deformation properties.

5. Good non adhesion and detachment, not adhering to substances with adhesion, and easy to detach in contact with substances with adhesion. It exhibits good weather resistance and moisture resistance.

6. Chemical etching can be performed to improve adhesion