Using glass fiber as the woven material, plain weave, twill weave, satin weave or other weaves are woven into a high-grade glass fiber cloth substrate. The fiber is first impregnated, and then the surface is coated with a smooth and uniform PTFE coating to enhance the release characteristics and make it Can resist the accumulation of pollutants and oil. In addition, it can resist most acids and alkalis. This fabric is very suitable for most applications that require increased surface texture. This fabric is very suitable for many mechanical applications, is dimensionally stable, and can operate in extreme temperatures and chemically corrosive environments. PTFE and silicone coated fabrics are designed for a variety of applications in different industries where high temperature, non-stick, chemical resistance and dimensional stability are important.

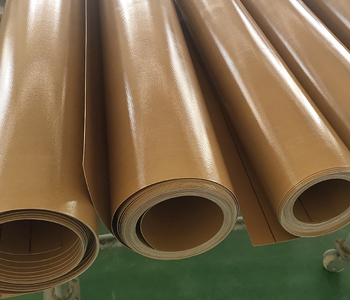

PTFE coated fabric with thickness ranging from 0.003 to 0.030. Our coating percentage varies from 15% to over 60% by weight.

Applications include: mold release fabric covering plastic sealing lines, bakeware, chemical-resistant gaskets or seals, lids for thermal laminators, welder pockets in the vinyl window industry, splash curtains, insulating jackets, belts, partitions, etc...

In addition, we can make the coating anti-ultraviolet, anti-wrinkle and anti-tear properties, and even semi-conductive to prevent the loss of static electricity!

High strength, light fiber, high temperature resistance, high strength, good toughness, smokeless when burning,corrosion resistance, anti-slip and other characteristics.

Industrial conveyor belt, printing and dyeing, microwave and other high temperature drying.