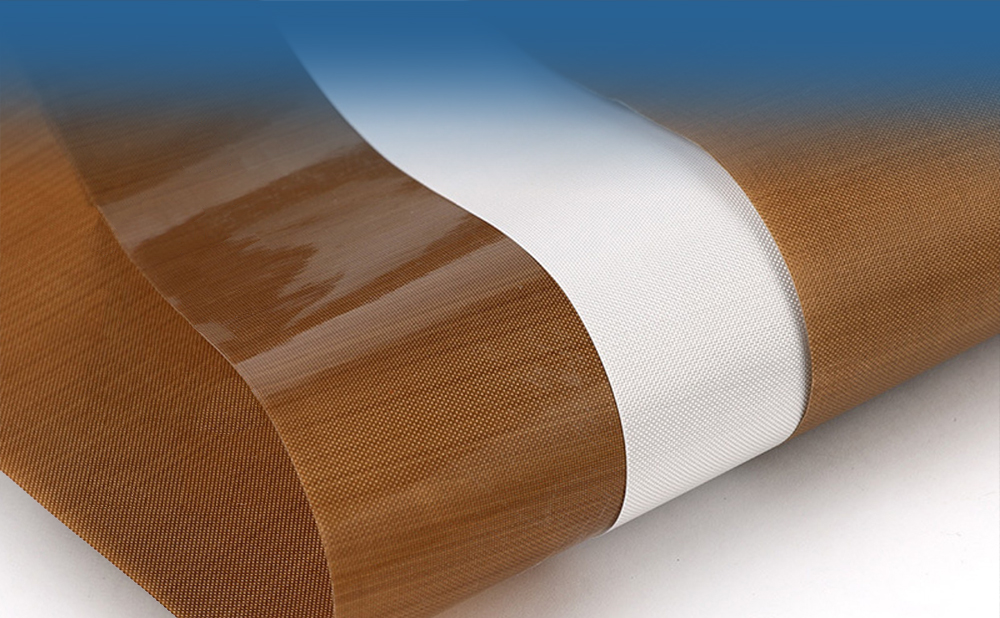

PTFE coated fiberglass fabrics using the highest quality woven fiberglass fabrics available.Our process first impregnates the fibers and then coats the surface with a smooth uniform PTFE coating, enhancing release characteristics, and making it resistant to build-up of contaminates and oils.In addition it repels attack by most acids and alkalis. The fabrics are well suited for most applications where increased surface texture is required. Ideally suited for many mechanical applications, the fabrics are dimensionally stable and operate at extreme temperatures and in chemically aggressive environments.

Our PTFE and Silicone coated fabrics are designed for a number of applications in diverse industries where high temperature, non-stick , chemically resistant and dimensionally stable characteristics are important.

We manufacture over 50 styles of PTFE coated fabrics from 0.003 to 0.030 thick. Our coating percentages range from 15% to over 60% by weight.

Most applications use our Standard Grade with a heavy PTFE coating and smooth surface. Applications include: Release fabric covering plastic sealing wires, baking sheets, chemical resistant gaskets or seals, covers for thermal laminating presses, and more!

In addition, we can make the coatings UV resistant, crease and tear resistant and even semi-conductive for static bleed-off!

• Packaging • Food Processing • Heat Sealing • Poly Bags • Baking Sheets • Release / Separator Sheets • Thermal Film Lamination • Gaskets / Diaphragms • Thermal Transfer Presses • High Temperature Belting • Curing and Drying

1. Anti adhesion, easy to clean. Easy to clean various oil stains, stains, or other attachments attached to its surface; Almost all adhesive substances such as paste, resin and paint can be simply removed;

2. Extremely low friction coefficient (0.05-0.1), making it the best choice for oil-free self-lubrication;

3. Superior temperature resistance, Teflon high-temperature resistant cloth can be used for a long time in the temperature range of -274 ℉ to 500 ℉. After practical application, if left continuously for 200 days at a high temperature of 482 ℉, not only will the strength not decrease, but also the weight will not decrease; When placed at a high temperature of 716 ℉ for 120 hours, the weight only decreases by about 0.6%; Under ultra-low temperatures of -292 ℉, it will not crack and maintain its original softness;

4. Safe and non-toxic, suitable for food production;

5. It can resist the corrosion of almost all Almost all;

6. Good dimensional stability and strong tensile strength, with good mechanical properties;

7. Teflon high-temperature cloth has good flexibility and folding resistance;

8. High insulation performance (low dielectric constant: 2.6, tangent below 0.0025);

9. Resistant to microwave, high frequency, UV, and infrared radiation.

| Type | Color | Thickness (mm) ±5% |

Base Fabric Weight (g/m) |

Product Weight (g/m) |

Tensile Strength (N/5cm) |

Tear Strength (N/5cm) |

||

| Radial | Zonal | Radial | Zonal | |||||

| 9008AJ | brown | 0.075 | 48 | 150 | 650 | 550 | 8 | 8 |

| 9008J | white | 0.075 | 48 | 150 | 600 | 500 | 6 | 6 |

| 9008BJ | black | 0.075 | 48 | 150 | 600 | 500 | 6 | 6 |

| 9010J | white | 0.095 | 105 | 180 | 850 | 750 | 7 | 7 |

| 9011AJ | brown | 0.105 | 105 | 190 | 1000 | 900 | 10 | 10 |

| 9012AJ | brown | 0.115 | 105 | 220 | 1150 | 1000 | 12 | 12 |

| 9013AJ | brown | 0.125 | 105 | 250 | 1200 | 1100 | 15 | 15 |

| 9013BJ | black | 0.125 | 105 | 250 | 1050 | 850 | 12 | 12 |

| 9013J | white | 0.125 | 105 | 250 | 950 | 850 | 12 | 12 |

| 9015AJ | brown | 0.14 | 105 | 300 | 1350 | 1250 | 18 | 18 |

| 9015BJ | black | 0.14 | 105 | 290 | 1300 | 1200 | 16 | 16 |

| 9018AJ | brown | 0.17 | 165 | 350 | 1750 | 1550 | 20 | 20 |

| 9018BJ | black | 0.17 | 165 | 350 | 1500 | 1300 | 15 | 15 |

| 9020AJ | brown | 0.2 | 165 | 425 | 1800 | 1600 | 20 | 20 |

| 9020BJ | black | 0.19 | 210 | 360 | 2000 | 1700 | 22 | 22 |

| 9025AJ | brown | 0.235 | 210 | 490 | 2200 | 1750 | 25 | 25 |

| 9025BJ | black | 0.23 | 210 | 480 | 2000 | 1700 | 25 | 25 |

| 9025J | white | 0.235 | 210 | 490 | 1800 | 1500 | 20 | 20 |

| 9030AJ | brown | 0.28 | 255 | 590 | 2400 | 1700 | 35 | 30 |

| 9030BJ | black | 0.28 | 255 | 580 | 2400 | 1700 | 35 | 30 |

| 9035AJ | brown | 0.32 | 255 | 630 | 2600 | 2000 | 40 | 35 |

| 9035BJ | black | 0.32 | 255 | 630 | 2600 | 2000 | 40 | 35 |

| 9036AJ | brown | 0.35 | 305 | 680 | 3200 | 2200 | 45 | 40 |

| 9036BJ | black | 0.36 | 305 | 730 | 3200 | 2200 | 45 | 40 |

| 9040AJ | brown | 0.38 | 350 | 780 | 3200 | 2100 | 45 | 40 |

| 9040BJ | black | 0.38 | 350 | 780 | 3000 | 2000 | 45 | 40 |

| 9055AJ | brown | 0.52 | 538 | 1050 | 3500 | 3000 | 100 | 80 |

| 9055J | white | 0.52 | 538 | 1050 | 3200 | 2800 | 80 | 60 |

| 9055BJ | black | 0.52 | 538 | 1050 | 3500 | 3000 | 100 | 80 |

| 9060BJ | black | 0.58 | 538 | 1150 | 3800 | 3300 | 120 | 100 |

| 9065AJ | brown | 0.63 | 578 | 1200 | 4000 | 3500 | 140 | 120 |

| 9065BJ | black | 0.63 | 578 | 1200 | 4000 | 3200 | 140 | 120 |

| 9065J | white | 0.63 | 578 | 1200 | 3800 | 3200 | 120 | 100 |

| 9075AJ | brown | 0.73 | 655 | 1400 | 4200 | 3800 | 180 | 160 |

| 9080AJ | brown | 0.78 | 740 | 1500 | 4500 | 4000 | 220 | 180 |

| 9080BJ | black | 0.73 | 665 | 1400 | 4200 | 3800 | 220 | 180 |

| 9080J | white | 0.73 | 665 | 1400 | 4000 | 3500 | 180 | 150 |

| 9090AJ | brown | 0.98 | 865 | 1850 | 5500 | 4500 | 250 | 200 |

| 9090BJ | black | 0.98 | 865 | 1850 | 5500 | 4500 | 250 | 200 |

| 9100AJ | brown | 0.98 | 910 | 1250 | 6000 | 5000 | 300 | 250 |

1. Anti adhesive lining, gaskets, blankets, and conveyor belts; According to the thickness, it is used for various conveyor belts, adhesive belts, sealing belts, etc. of drying machinery;

2. Welding cloth, plastic sheet, film, and heat sealing pressure strip used for welding and sealing plastic products;

3. Electrical high insulation, electrical insulation tape base, spacer, gasket, and lining ring. High frequency copper clad plate;

4. Heat-resistant cladding, laminated substrate, and insulation body wrapping;

5. Microwave pads, oven slices, food drying;

6. Adhesive tape, transfer printing hot tablecloth, carpet adhesive curing conveyor belt, rubber vulcanizing conveyor belt, abrasive sheet curing release cloth, etc;

7. Pressure sensitive adhesive tape substrate;

8. Architectural membrane materials: various sports venues' roofs, station pavilions, umbrellas, landscape awnings, etc;

9. Used for anti-corrosion coating of various petrochemical pipelines, environmental desulfurization of waste gas from power plants, etc;

10. Flexible compensator, friction material, grinding wheel slicing;

11. After special processing, "anti-static cloth" can be made.