manufactures its PTFE coated fiberglass tape using the latest coating technology. First we impregnate the fiberglass substrate, then lay down multiple coats of PTFE to build pure PTFE thickness and finally, prepare or “etch” one side for coating with high temperature Silicone pressure sensitive adhesive. By combining premium quality PTFE Coated Fiberglass Fabrics with High Temperature (500 deg F) Silicone adhesive systems, we've made an adhesive tape designed to operate in a wide variety of environments including extreme temperatures and chemical exposure… and releasing cleanly from almost any material!

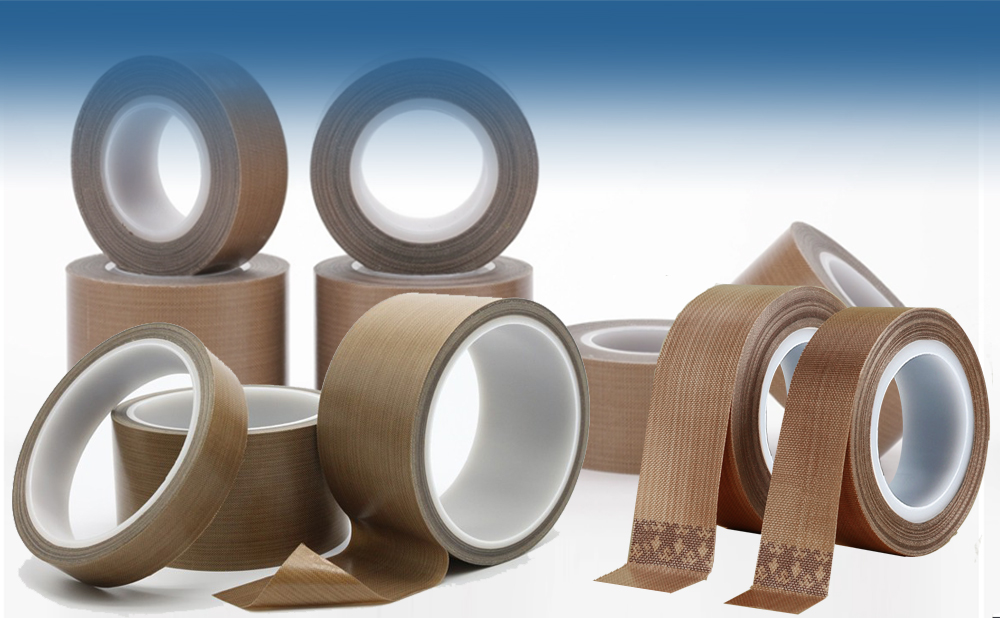

Our tapes are manufactured here in our plant using high temperature silicone or high tack acrylic adhesives. Combining premium backing materials with high performance adhesives, we manufacture some of the most specialized tapes available.

Many of our own PTFE coated fiberglass fabrics are made bondable on one side and are converted into adhesive tapes.

Our tapes enter service in a number of diverse industries including: Packaging, Food Processing, Aerospace, Electrical / Electronics, Molding Heat sealing/cutting machine of food and medicine plastic packaging industry, and high speed heat sealing machine,Anti-adhesive treatment on the surface of drying drums, anti-adhesive treatment on the surface of the laminating machine, anti-adhesive treatment on the surface of the drying drums etc…

Applications include heat sealing plastics/bags, release liners for composite work, bearing surfaces, guide rail / chute lining and many other non-stick, low friction applications.

1. Heat sealing/cutting machine of food and medicine plastic packaging industry, and high speed heat sealing machine.

2. Anti-adhesive treatment on the surface of drying drums; anti-adhesive treatment on the surface of the laminating machine; anti-adhesive treatment on the surface of the drying drums.

3. Application of anti-adhesive, friction reducing.

1. Weather, anti-aging resistance between low temperature -196℃ and high temperature 300℃.

For example, if it is placed at a high temperature of 250℃ for 200 days, the strength and the weight won't be reduced. Be placed at 350℃ for 120 hours, the weight will only decrease by about 0.6%; Maintain the original softness at -180℃.

2. Non-stick: The surface is smooth and it is not easy to adhere to any substance. Easy to clean; all adhesive substances, such as paste, resin, paint, etc. can be easily removed.

3. Chemically resistant, which can resistant strong acids, alkalis, aqua regia and various organic solvent.

4. Medicament resistance and non-toxic. Resistant all pharmaceutical items.

5. High insulation performance (permittivity: 2.6, tangent below 0.0025), UV protection, anti-static.

6. Fire retardant.

7. Easy to use and long service life.